In the context of consumer goods, sustainability is more than a positive practice: it is now a crucial component of every business strategy. As new markets emerge and consumers become more environmentally friendly, alongside government policies becoming more rapidly environmentally stringent, manufacturers are turning to materials that fulfill performance requirements while also considering the impact on nature. Aluminium is certainly emerging as a primary candidate in this evolution due to its increasing market demand alongside its historically known lightweight and durable nature.

Purchasers seeking to improve the sustainability level of consumer goods should consider employing a precision sheet metal fabricator specialized in aluminium fabrication. Such fabricators invariably improve sustainability performance, product innovation, and competitiveness. This article analyzes the role of the aluminium fabrication industry along with its implications in sustainability pertaining to consumer product fabrication.

Why Aluminium Stands Out As A Sustainable Material

Aluminium stands out to be an alloy of choice among consumers due to its range of mechanical properties along with its particular environment-friendly advantages that aid in the diversification of electronics, furniture, and even transportation accessories.

Key Sustainability Features

- Recyclability: Aluminium can be recycled ad infinitum without degradation of any strength or quality, granting it a perpetual, true circular identity.

- Energy Efficiency: The energy consumption and emissions are greatly reduced because recycled aluminum only uses 5% of the energy needed to produce primary aluminum.

- Lightweight Strength: The energy and carbon footprint is reduced by shipping stronger Lightweight products due to aluminum’s strength to weight ratio.

- Corrosion Resistance: Reduced product replacement cycle is achieved by not frequently replacing products adding to the intercepting waste.

Aluminum fabricators that precision machine metal can leverage the for B2B partners to produce purposeful consumer goods to help achieve long term sustainability goals.

Applications of Aluminium Fabrication in Consumer Products

Because both ergonomics and esthetics are pivotal Aluminum’s focus, A wide range of consumer products is made possible and supported with.

Electronics and Home Appliances

To aid with modern consumer products aesthetics as well as functionality, unlike other materials aluminum is capable of carrying power making it thermally conductive. Designed for lightweight electronic enclosures, the aluminum provides adequate heat dissipation and cooling, lowering the use of cooling components, extending life span.

Furniture and Interior Fixtures

Less emissions and resource-make up for look are driven due to the strength of were brittle mudguards and the look of its aluminum helping reduce the number of replacements and returns making the aid dealer reduce waste.

Sports and Outdoor Equipment

When considering outdoor products like bicycles, camping gear, and portable power units, aluminium is a material of choice due to its strength without bulk. Products such as these benefit from the endurance and stubborn lightweight properties of the material, making it ideal for mobile or rugged use.

Collaboration with a precision sheet metal fabricator is favorable in achieving accurate material cutting, forming, assembling, and ensuring product quality and performance consistency through precision engineering.

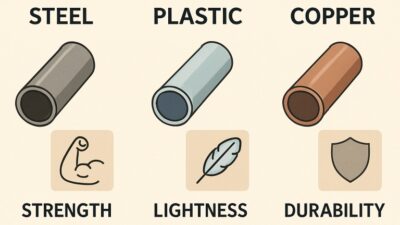

Aluminium vs. Other Metals in Sustainable Manufacturing

In most manufacturing environments, types of steel and copper are still viewed as important however, when it comes to consumer product design, aluminium clearly has the sustainability edge.

- Aluminium vs Steel: Generally, aluminium is lighter and far more resistant to corrosion. While steel is stronger in certain applications, aluminium provides similar results at a fraction of the weight.

- Aluminium vs Copper: Copper has far better conductivity but is heavier and more expensive. In applications that do not require high levels of conductivity, aluminium is a more sustainable option.

Many businesses have relied on copper sheet metal fabrication, but in an effort to improve environmental and economic performance, they are now switching to precision sheet metal fabrication for their aluminium designs where possible.

The Contribution of Fabricators to the Sustainability of Aluminum

Experts in precision fabrication have the capabilities to guide clients through design, prototyping, production, and post-processing. From the outset, choosing the right partner in manufacturing greatly determines the extent of recovery in environmental impacts from aluminum fabrication processes.

Design for Sustainability

The Adjustments fabricators undertake include designing multi-part components that are more easily assembled and incorporate fewer fastening elements. The design efficiencies translate to lower material and energy expenditures for production.

Features of Sustainable Production Processes

The use of advanced technology for cutting, forming, applicative laser cutting, sequencing machine tools, or automated bending machines enhances the abilities of a fabricator to utilize the material while eliminating waste.

Eco Friendly Surface Treatments

Sustainable practices are being adopted to a wide extent by fabricators through the application of eco-friendly anodizing processes for coating and powders. Such practices reduce emissions and corrosion at the same time whilst improving visual appeal.

Support with Sustainable Logistics and Packaging

Advanced sheet metal fabricators have the capability to aid sustainable logistics with the designs of reusable packaging, optimized shipping configurations, proficient stacking and gracious box-like structures.

Working with such forward looking fabricators allows companies to address issues of sustainability right from product design to logistics and delivery, incorporating environmentally sound practices at every level.

Future Projections: The Use of Aluminium in Sustainable Consumer Products

The sustainability focus of consumer products is here to stay, and to address the challenge, aluminium fabrication has sophisticated demand. be it modernistic furniture or high-end gadget, aluminium allows for unprecedented eco-friendly industrial design options devoid of undermining environmental considerations.

Aluminium Adoption Strategic Policies

- Consumer Awareness: There is a significant increase in the number of shoppers willing to switch to eco-friendly and recyclable materials for their products.

- Regulatory Frameworks: Governments across the world have placed tougher guidelines on waste and carbon emissions, which makes aluminium’s recyclability a differentiating factor.

- Green Certifications:Increased number of B2B retailers and distributors are now preferring suppliers with available third party-sustainability certifications which can be accomplished with aluminium-based designs.

Undoubtedly, the foremost challenge is how to create eco-friendly, innovative products. Partnering with a precision sheet metal fabricator that makes aluminium primary processes is the easiest answer. Now manufacturers are able to surpass sufficing expectations and achieve stronger brand perception amid competition—and thus position themselves strategically for greater profit.

Final Thoughts

The modern market that focuses on sustainability is rapidly changing, and the construction process of consumer products is being rethought in terms of their design and assembly processes. The ever-growing combination of strength, lightness, and recyclability makes aluminium one of the most remarkable materials from a sustainability point of view.

It does not matter if you are coming from copper sheet metal fabrication or starting a new product line, a precision sheet metal fabricator will help you gain both performance and environmental precision expertly. For aluminum based B2B companies trying to mark themselves as pioneers in innovative green solutions, the metal demonstrates readiness for the future.