Introduction

As construction projects become more complex and demanding, the importance of choosing robust, efficient, and cost-effective piping solutions has never been greater. Today’s builders and engineers have access to various advanced materials and cutting-edge technologies that address durability, sustainability, and installation ease. If you’re sourcing piping products or seeking expert guidance, partnering with experienced suppliers like Cruco Mill & Industrial Supply can streamline procurement and ensure your project meets modern standards.

The piping sector has evolved substantially, driven by advancements in materials science and digital innovation. Today’s solutions, from smart monitoring systems to eco-friendly rehabilitative techniques, are tailored to support longevity and performance. The right partner can help guide your selection process, identify best-suited technologies, and optimize for both cost and durability.

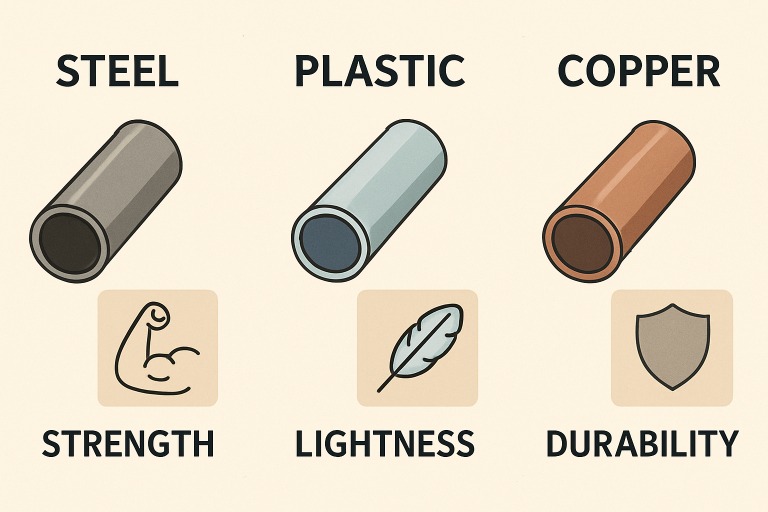

Choosing the Right Pipe Material

Selecting an appropriate pipe material is foundational for the success of any construction project. Each type of material brings a unique combination of advantages to the table:

- Steel Pipes: Valued for their exceptional strength, steel pipes are ideal in high-pressure environments and for carrying heavy loads. Their robustness makes them a staple in industrial and commercial construction.

- Plastic Pipes: These include options such as PVC, CPVC, and PEX, all known for their corrosion resistance, lightweight handling, and versatility. Plastic piping is popular for residential applications and is especially effective where quick installation is a priority.

- Copper Pipes: Copper pipes are frequently used for potable water supply lines and are prized for their longevity, reliability, and natural resistance to bacteria. Their smooth surface minimizes pressure loss and scaling over decades of use.

Innovations in Pipe Technology

One of the most significant advancements in the field of piping is the integration of innovative technologies. Modern piped systems now incorporate sensors that offer real-time data on flow, pressure, leakage, and pipe integrity. Such innovative pipe systems facilitate timely maintenance and safeguard infrastructure from catastrophic failures. For instance, bright piping has played a vital role in streamlining shipyards and municipal water systems maintenance, as highlighted in coverage of innovative water infrastructure.

Additionally, robotic solutions have emerged as a boon for in-situ pipe rehabilitation. Automated crawlers and inspection tools can navigate difficult-to-access pipelines, identify issues, perform targeted repairs, extend the asset lifespan, and reduce downtime.

Installation Best Practices

Proper installation techniques are critical in preventing future failures and maximizing the value of any piping system. First, precise alignment and secure joinery of pipes ensure seamless flow and prevent leaks. Contractors must closely follow manufacturer specifications and comply with relevant industry standards, such as those set by the American National Standards Institute or ASTM International.

Pressure testing before permitting a system to go live is equally crucial. This proactive step can uncover vulnerabilities in the assembly before use. It is recommended that you use calibrated testing equipment and document all results, creating an audit trail for project owners and inspectors.

Maintenance and Longevity

Maintaining pipes is a continuous process. Scheduled inspections, using manual techniques and remote monitoring devices, allow teams to spot corrosion, blockages, or leaks early. Cleaning regimens—such as flushing, pigging, or chemical treatments—help minimize scale buildup and microbial growth inside pipes.

Equally important is prompt repair. Addressing minor cracks or joint weaknesses before they escalate can save significant repair costs and prevent system shutdowns. A strong maintenance protocol reduces risk and ensures compliance with health and safety standards. For best results, consider a holistic maintenance plan as recommended in guides specifying piping for high-performance projects.

Environmental Considerations

Eco-conscious construction practices are shaping the piping sector as well. Using recycled or sustainably sourced materials can lower a project’s environmental impact. Rehabilitating existing pipes—by lining them with composites or advanced polymers—often proves more eco-friendly and less disruptive than full-scale pipeline replacement. Innovations such as multi-use robots for trenchless rehabilitation or non-invasive leak detection are steadily gaining traction within the industry.

Adopting sustainable materials, minimizing waste during installation, and integrating energy-efficient manufacturing processes can all contribute to greener project outcomes, aligning with regulatory requirements and client expectations for environmentally responsible construction.

Cost Implications

While budget considerations naturally influence material and technology choices, assessing the total cost of ownership is essential. High-quality pipes and modern installation methods may carry higher upfront costs but can significantly reduce long-term expenses through fewer repairs, lower maintenance intervals, and prolonged service life. Decision-makers should evaluate lifecycle costs alongside initial procurement to derive the best overall value for their projects.

Conclusion

Modern construction places increased demands on piping systems to perform reliably over decades, adapt to new technologies, and deliver value from financial and sustainability perspectives. By understanding the strengths of various materials, leveraging technological advancements, and implementing rigorous installation and maintenance practices, construction professionals can build projects with lasting resilience and efficiency. Sourcing through trusted partners further ensures access to top-tier products and expert support, setting each new infrastructure development up for success.