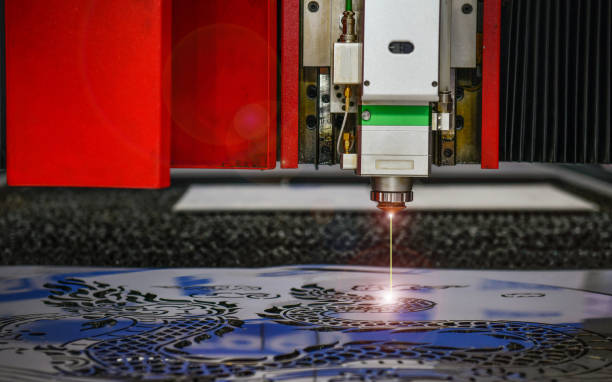

In 2025, Laser cutting machine are powering innovation and precision across a wide range of industries. From metal fabrication to medical device manufacturing, these machines are transforming how businesses cut, shape, and engrave materials. Their unmatched accuracy, efficiency, and versatility make them indispensable in high-demand sectors like automotive, aerospace, electronics, and fashion. Whether it’s CO₂ or fiber laser technology, manufacturers are leveraging these machines to streamline production, reduce waste, and meet the growing demand for customization and complexity. If you’re exploring industrial applications for laser cutting, here are the top industries where these machines are making a significant impact this year.

Here Are The Top 9 Industries Where Laser Cutting Machines Are Used

Metal fabrication

The metal fabrication industry relies heavily on fiber laser cutting machines to process materials like stainless steel, carbon steel, aluminium, and copper. These machines offer high-speed cutting with clean edges, minimal waste, and unmatched accuracy. Whether it’s sheet metal components or custom enclosures, laser cutting ensures consistent quality and efficient production.

Manufacturers benefit from reduced manual labour, improved productivity, and the flexibility to create complex geometries. With the growing demand for precision in construction, machinery, and infrastructure projects, laser cutting remains a key asset in modern metalworking.

Automotive industry

In the automotive sector, laser-cutting machines streamline the manufacturing of vehicle components such as body panels, brackets, exhaust systems, and structural parts. Their precision and repeatability make them ideal for prototyping and mass production. CO₂ and fiber lasers can cut metals and plastics with ease, enhancing workflow speed and reducing material waste.

Additionally, laser cutting machines enable the production of lightweight, high-strength components critical to modern vehicle design. As electric vehicle manufacturing grows, the need for high-precision laser-cut parts is driving increased adoption in the automotive industry.

Electronics & electrical

Laser-cutting machines play a critical role in the electronics and electrical industry, particularly for fabricating intricate parts like printed circuit boards (PCBs), connectors, and micro enclosures. These applications demand high-precision, non-contact processing to avoid damaging delicate materials.

CO₂ and fiber lasers can cut with micron-level accuracy, enabling manufacturers to maintain strict tolerances and boost product reliability. The ability to cut, drill, and engrave small components makes laser technology indispensable in consumer electronics, telecom equipment, and power systems manufacturing.

Signage & advertising

CO₂ laser cutting machines are a staple in the signage and advertising industry. They are used to cut different materials such as acrylic, MDF, plastic, and vinyl for custom signs, display panels, and promotional materials. Laser cutters enable the creation of intricate lettering, logos, and backlit effects that elevate brand visibility.

They also support both cutting and engraving functions, allowing for highly personalized designs. As the demand for customized and eye-catching visual communication grows, laser technology offers unmatched speed, detail, and flexibility for signage professionals.

Furniture & interior design

The furniture and interior design industry leverages CO₂ laser cutters to craft modern and artistic designs from wood, MDF, acrylic, and leather. These machines allow for intricate detailing in wall panels, room dividers, furniture pieces, and decorative accents. Designers benefit from the flexibility to experiment with patterns, textures, and customized elements.

Laser cutting ensures clean, precise cuts without splintering or burning, making it ideal for creating high-quality finishes. It also speeds up prototyping and enables mass customization—an increasing trend in home and office decor.

Packaging industry

Laser cutting machines are transforming the packaging industry by offering precise, customizable cutting and scoring for prototypes, templates, and production runs. CO₂ lasers are particularly effective for paper, cardboard, and plastic packaging materials. Brands can create intricate packaging designs, including embossed effects and die cuts, with sharp edges and consistent results.

Laser cutters enable quick turnarounds, small batch production, and cost-effective customization—key advantages for high-end, promotional, and e-commerce packaging. As brands seek to stand out on retail shelves, laser-cut packaging offers both functionality and aesthetic appeal.

Textile & apparel

CO₂ laser cutting machines are widely used in the textile and apparel industry to cut fabric, leather, lace, and synthetic materials with precision. They allow for high-speed pattern cutting, applique design, embroidery trimming, and customized fashion pieces. Laser technology ensures clean edges, no fraying, and reduced material handling, boosting both efficiency and quality.

Designers and manufacturers appreciate the versatility of both mass production and small-scale customization. As fashion trends demand faster turnaround and personalized garments, laser cutting provides the perfect solution for modern textile processing.

Aerospace & defense

In aerospace and defense, laser cutting machines are valued for their ability to produce lightweight, high-strength components with strict tolerances. These industries require materials like titanium, aluminium alloys, and composite sheets to be cut with extreme precision.

Laser cutters provide clean edges and reduce heat-affected zones, which is crucial for structural integrity and safety. Applications include engine parts, structural frames, and electronic enclosures. With increased emphasis on performance, efficiency, and weight reduction, laser cutting remains a vital technology in aviation and defence manufacturing.

Medical device manufacturing

The medical industry depends on laser cutting to produce surgical tools, stents, implants, and precision electronic components. Fiber lasers deliver the accuracy required for cutting ultra-thin metals and biocompatible materials without deformation. Clean cuts and smooth edges are essential for medical applications where sterility and safety are paramount.

Laser technology enables consistent production of intricate shapes with minimal material waste, ideal for mass production and custom manufacturing. The demand for advanced healthcare solutions is rising because the laser cutting machine plays a pivotal role in medical innovation and device production.

The Bottom Line

Laser cutting machines have revolutionized a wide range of industries by delivering unmatched precision, efficiency, and versatility. From heavy-duty sectors like metal fabrication and aerospace to creative fields such as signage and interior design, these machines will continue to redefine manufacturing standards in 2025. As industries demand faster turnaround, greater customization, and higher quality, investing in the right laser cutting technology becomes not just beneficial—but essential. Whether you’re scaling up operations or innovating with new materials, understanding the applications across these top industries can help you make more informed, future-proof decisions.