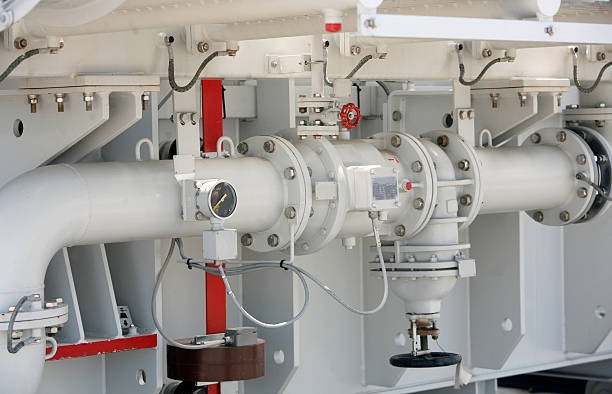

Pneumatic butterfly valves require careful consideration when being sourced for large-scale projects. Their thorough examination is important to make sure that these valves operate as intended. They are employed in virtually every industry such as water treatment facilities, chemical plants, HVAC, and even power plants because of their proficiency in managing the flow of both liquids and gases. In this paper, we will look at the most critical factors that need to be examined when sourcing butterfly valves and how a vendor’s choice affects the success of large scale projects. Also, we shall look into how an electric butterfly valve factory helps modern industry improve valve body components.

Valve Size and Specifications

The first thing that you need to look at when selecting pneumatic butterfly valves for big projects is the valve size and specifications. As with most valves, the pipe diameter as well as flow rate dictate the size of butterfly valve that needs to be installed. Steam trap valves must also align with the specific requirements of the project in order to achieve maximum effectiveness. The valve needs to let through the requisite flow capacity of your system without having a pressure drop across the valve. This makes sure that the entire system works as expected and saves energy that would otherwise be wasted due to oversizing or under-sizing the system. Additionally, what also needs to be determined is the working conditions, meaning the pressure and temperature the valve will be exposed to, as well as the nature of a working fluid or gas. For instance, certain fluids contain aggressive chemical compounds which can only be controlled using valves constructed from corrosion resistant materials. With specific knowledge of the parameters of the system application, one can reliably ensure that the selected valve functions efficiently within the system, thereby achieving minimal interruption and maximum performance.

Working alongside a trusted supplier of butterfly valves makes this easier since they can assist you with choosing the size, material, and other features suited for your system.

Compatibility With Material and Corrosion Resistance

When selecting a soft seated butterfly valve, one has to consider the material compatibility and durability of the valve. Various operational conditions will have to be taken into consideration such as high pressures, extreme temperatures, and even corrosive environments. Industrial applications dealing with fluids like chemicals or high pressure gas systems require utmost resistance to abrasion, corrosion and other extreme conditions. The type of fluid or gas that the valve will control dictates the choice of materials for the valve body and the disc. For instance, stainless steel is often used in food processing or in the chemical industry because of its superb corrosion resistance. For less severe conditions, carbon steel or cast iron will likely be adequate. One also has to take into account the predicted wear and tear as compared to the expected lifespan of the system. High quality materials also enhance the performance of the valve by ensuring very low maintenance and the risk of failure will be zero. Because the right material has a profound impact on durability, it also leads to a reduction in operational and replacement costs which can increase the overall cost of the asset.

A reputable butterfly valve supplier will help choose materials that will work well with the operational parameters of the valve, ensuring its long life with minimum interruptions.

Control and Actuation of Valves

Pneumatic butterfly valves can be powered by a butterfly valve actuator that incorporates a pneumatic actuator for valve disc motion control. When procuring these valves, one must pay special attention to the methods of valve actuation and control that are available. The power features of actuators differ by torque, speed, response time, and several other factors, therefore selecting an actuator that meets the requirements of the specific system in question is imperative. Positioners and modulating controllers are becoming increasingly popular in sophisticated applications, even though pneumatic actuators are great due to their simplicity and low price. The use of positioners, solenoids, and even superordinate automatic systems further enhances the performance of a butterfly valve and increases its earning potential by providing more control and accuracy over flexible parameters. These systems enhance remote diagnostics, monitoring, and accurate adjustments of valve movement automation to control fluid flow through the valve. The control system enables the user to make the valve more responsive to pressure or flow changes, thereby improving the overall efficiency of the system. When obtaining valves, make certain that valve control actuators you intend to use can be integrated with your configurable control systems.

Engaging a reputable butterfly valve supplier assists in choosing the proper actuation system and provides insights on how to integrate the actuator’s capabilities with the requirements of your project.

Pressure Rating and Flow Control

When looking for butterfly valves for vast projects, pressure rating stands out as one of the most critical specifications. The pressure rating denotes the maximum pressure the valve can withstand without failing and it is crucial to ensure the valve can cope with the system’s operational pressure. In high-pressure systems, the right valves need to be selected to ensure that the expected operating pressures will not damage the valve or system’s integrity. Also, a valve’s flow control characteristics are essential in supporting efficient operations. Butterfly valves are ideal for modulating flow control because they can both turn on or off the flow and throttle the flow rate with precision. The flow coefficient (Cv) is one of the most significant valve measures to capture since it defines the level of fluid flow through a given valve in the system. This is very important in industries like water treatment where the level of flow needs to be regulated precisely to achieve stability of the surrounding system. Adequately adjusting the pressure rating of the valves together with the features defining flow control will ensure efficiency and safety for the system and the project goals are met.

Conclusion

Working with a butterfly valve supplier guarantees that these requirements are catered to the needs of the operations on the project. Conclusion Obtaining butterfly valves for pneumatic applications in large projects calls for careful attention to some considerations such as valve dimensions, construction materials, type of actuation, pressure rating, and serviceability. Experienced suppliers of butterfly valves will always ensure that the right valves are selected for the specific requirements of the project. Moreover, right selection of a valve with the proper type of actuation and control will further enhance the overall energy efficiency. The best electric butterfly valve companies that fabricate valves are primarily for offering advanced onion dome solutions that go hand in hand with the functionality of the electromagnetic valves, particularly for control and automation. With regard to these critical components, large scale projects can be undertaken with the promise that it will be completed on time and within budget while ensuring that operation, safety management, and maintenance activities will be reduced to the bare minimum. By the right selection together with expert advice from the trusted suppliers of butterfly valves, it is now possible for one’s project to use the best valves for immediate productivity without compromising its desired built to last assurance.